This article by Alpine Overhead Doors originally appeared in the Winter 2024 Edition of DASMA’s magazine, Door + Access Systems. Republished with permission.

> Click here to view/download as a PDF.

Editor’s note:

In this article, the team at Alpine Overhead Doors outline common mistakes installers make when sourcing and installing rolling doors and the issues that these errors can cause. Read on to learn how to gain critical insight and avoid these common pitfalls.

Rolling steel doors offer many benefits for countless commercial applications. They are versatile, durable, and require little maintenance over time. However, their durability and longevity can be compromised if they aren’t properly specified or installed.

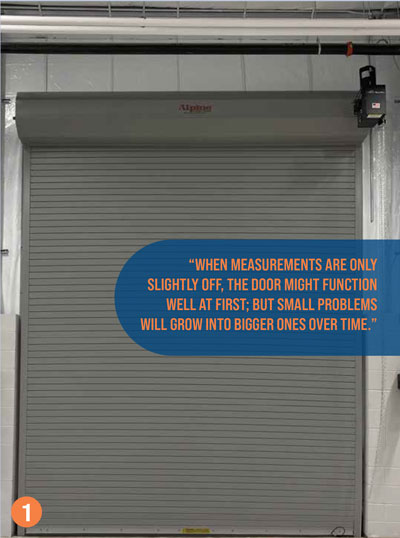

1. Inaccurate measurements

It might be surprising that something so straightforward can go so wrong.

Misjudging the width, height, headroom, or side room required can lead to inaccurate measurements. Even when taken accurately, details can often be misunderstood or poorly communicated.

Whatever the cause, incorrect measurements lead to installation delays — especially if the door doesn’t fit the opening. You may need to modify the door or opening to compensate, which can add significant delays and project costs. In extreme cases, you may be left with no other option but to reorder the door. All of this is avoidable when accurate measurements are taken and properly communicated from the start.

When measurements are only slightly off, the door might function well at first; but small problems will grow into bigger ones over time. For instance, operational issues such as difficulty opening and closing the door due to a misalignment may arise, which can result in increased wear and tear on the door. Certain dimensional errors can lead to gaps, which compromise energy efficiency.

In order to avoid these problems, be sure to measure to the nearest fraction of an inch using an accurate traditional or laser tape measure. Don’t forget to account for additional clearance or space needed for operation, including operators, sensing devices, switches, or control stations/ panels. Be mindful of obstructions such as sprinkler pipes, conduit, ballasts, and rafters.

Pipes, conduit, etc. are a few of the many potential obstructions that can affect measurements.

2. Poor communication

All too often, buyers and suppliers will have different definitions for common door measurement terms. You must ensure that you, your entire team, and your suppliers are all speaking the same language.

Terms like “rough opening,” “wall opening,” “clear opening,” and “door opening” sound similar, but may have different meanings depending on who you are speaking to. Be sure to take a few minutes when working with your suppliers to understand their exact definitions of dimensional terminology.

When working with architectural drawings, be sure to read and communicate the proper dimensions. Look carefully, as it can be easy to pick up the wrong numbers — especially when rushing. For instance, width and height can easily be swapped; width should always come before height. While this may sound pretty simple, mistakes do happen. If you’re ever in doubt, then please ask your manufacturer/supplier to double check the drawings to make sure you are using the correct measurements.

The wide curtain assembly shown is attached to a lifting cradle with cushioning at the bottom of the curtain to prevent damage.

Two boom lifts are used to raise the wide curtain assembly into position.

3. Damaging the curtain prior to installation

Rolling steel doors are extremely durable once installed. However, they can be damaged during installation if not handled properly.

Although curtains are large and heavy components, they’re not indestructible. Installers must be mindful that they aren’t dealing with structural steel but lighter gauge steel. Mishandling curtains leads to sight damage, which often leads to avoidable repair or replacement costs.

One of the most common handling mistakes is not using enough slings or choke-slinging the curtain to lift it. The sling applies too much force, which damages the slats — particularly when pads or cushions aren’t used.

Properly lifting and placing a curtain requires equipment that is designed to easily handle the weight, such as a hand-operated lift truck, chain blocks, forklift, or a boom lift. These options, when properly used, will distribute the lifting force and thus reduce the likelihood of damaging the curtain. While it might not be practical for lower-volume installers to purchase this machinery, they should consider renting it and including the rental cost as part of the installation cost.

Curtains can also be damaged when prepared for and during transport. Avoid choke slinging or over-strapping them, especially if the door is transferred during the shipping process. Make sure they stay covered — particularly when making long trips. Don’t step on them either!

Bottom line: when it comes to shipping and installing rolling steel doors, handle with care!

4. Under- or over-specification

Rolling steel doors are available with many options for material, finishes, operation, insulation, fire and wind ratings, and much more. It’s important to specify the right options and components for a door’s use and operating environment.

Let’s examine two different applications for rolling grilles as examples: a residential parking garage versus a storefront. The grille in the residential garage will be cycled many times during the day as cars enter and leave the building. As such, it should have more durable structural angles and guides, be designed with stronger materials, and preferably utilize an operator with a higher cycle rating.

This rolling door system features a high-speed operator, which helps reduce energy costs and increases productivity.

Opening and closing speed should be considered; for high-cycle applications like this, a high-speed operator is required. Conversely, a storefront grille that’s not likely to cycle more than once daily could use a standard motor (or even be operated manually) and could be constructed with standard material for the angles and guides. While both grilles may appear the same at quick glance, utilizing the configurations and options for their specific use will help ensure that they remain reliable for many years to come.

5. Improper finishes

Selecting the right finish is also crucial but can be confusing since there are several options. Materials such as stainless, galvanized, or aluminum come in a variety of finishes. They may also come prepainted in standard factory colors or powder coated in a range of available colors.

The ideal choice depends on the environmental conditions the door will be subjected to as well as aesthetic considerations. For instance, doors that may be subjected to extreme water or corrosive environments require 300-series stainless steel. While the upgraded finish will increase upfront costs, the door will better withstand the elements and last much longer, which will ultimately reduce the lifetime cost of the door.

Wind-rated doors require other considerations. You’ll mostly need to make sure it’s rated for the specific wind load and location. To figure out the optimal rating, use a wind load or tornado calculation platform, such as the ATC Hazards by Location website, that considers site-specific details such as geography and other critical data.

Also, for wind-, storm-, and fire-rated doors, always be sure to follow applicable guidelines as set by the Authorities Having Jurisdiction (AHJ), who maintain and enforce codes for requirements and testing.

6. Inadequate preparation of opening

Failing to properly prepare the door opening before installation can also cause headaches both immediately and in the future.

Insufficient preparation can lead to uneven or noisy door operation, premature wear, and difficulty sealing (thus allowing air or water infiltration).

Good preparation starts with a full inspection of the opening prior to installation. Ensure the opening is square, level, and plumb. Address any minor structural issues before installing the door. You can often compensate for these imperfections with shims or by utilizing guides with slotted mounting holes.

7. Ignoring structural issues

In some cases, you may be faced with bigger structural issues, such as uneven walls, weak supporting elements, or inadequate jamb and header construction. These must be remedied as they can lead to structural failure, dangerous conditions, and costly repairs in the long run. You may be able to address smaller issues without additional help. However, if you have any doubt, then bring your concerns to the building owner and recommend that they consult a structural engineer to make sure the building can properly support the door; this step is especially important for fire-rated and wind-loaded doors.

8. Out of level pipe shaft

Many operating issues stem from an out-of- level pipe shaft (or barrel). Since the door hangs from and wraps around the pipe shaft, it is absolutely essential that it is perfectly level. If the pipe shaft is not level, then the curtain can shift and cut into the brackets, which causes operational issues such as binding, noise, and premature wear (among others).

To avoid pipe shaft complications, use an accurate leveling device to ensure that the shaft is perfectly horizontal during installation. Check at multiple points along the length of the shaft.

9. Improper guide (track) installation

The guides hold the horizontal position of the door. If they are not properly positioned, then the door is likely to hang up or generate excessive noise during opening and closing.

Poorly installed guides can also lead to uneven wear, binding, and premature bearing failure. In more severe cases, the curtain can become damaged.

To avoid guide installation problems, follow the manufacturer’s spacing, guide gap, and alignment guidelines closely. Use precise measurement and inspection tools such as laser levels and go/no-go gages, make sure the tracks are both parallel to each other and perpendicular to the floor, and ensure that there’s adequate clearance between the door curtain and the guides. Failing to do so could lead to many issues — especially for wind load doors. These doors require precisely set guide gaps in order to help prevent the curtains from coming out of the guides.

10. Incorrect spring tension

Spring tension refers to the amount of force exerted by the torsion springs inside the pipe shaft assembly. These springs counterbalance the weight of the curtain (making it easier to open) and control its descent. When properly set, the springs reduce strain on the operator, which ensures smooth and consistent operation.

Improper spring tension can cause several problems. For example, over-tensioning may shorten the life cycle of the pipe shaft, while under-tensioning may cause the door to fall or overload the operator. The door may be difficult to open or too heavy to lift.

To avoid tension issues, follow the manufacturer’s instructions and pretension requirements closely. Remember that rolling doors should be tensioned in their fully open position and not when closed.

11. Incorrect limit adjustments

Motorized operators contain limit switches that control a curtain’s travel limits by stopping the door at predetermined positions when opening and closing. If the open limit is not properly set, then the door might not fully open, which obstructs passage. If it is set too high, then it causes the bottom bar to hit the stops/bellmouths. Over time, this causes the stops to loosen, which results in gradual damage to the curtain.

Conversely, if the close limit is not properly set, then other problems may arise. The door may stop too high and leave a gap at the bottom instead of creating a proper seal. The opening then allows infiltration of air, water, insects, and other environmental threats.

Improper setting can also cause a door to overtravel, thus damaging the curtain or floor. It can also create a visible “crunching” effect, where individual slats push in or out at an angle instead of perpendicular to the ground. Additionally, if the motor runs longer than needed, then it can lead to increased strain on the operator.

The proper setting of limit switches is important for safe, efficient, and long-lasting operation of rolling steel doors. Please consult the motor operator’s installation manual to make sure you get it right.

12. Inadequate lubrication

As with all mechanical systems, rolling doors require proper lubrication upon installation and over time. While it’s a relatively simple task, it’s often overlooked. Failure to do so will immediately cause increased component friction, wear, and noisy, inconsistent operation. Longer-term problems include failure of the bearings and other moving parts, increased energy consumption, and higher maintenance costs.

To avoid lubrication issues, apply manufacturer-recommended lubricants on all specified points such as the guides and gear teeth (or worm gear speed reducer if the door is electrically operated). Avoid over-lubrication, which can attract dirt and debris. Establish a regular lubrication schedule and educate your customers on the importance of proper lubrication.

Once a door is completely installed, it’s tempting to just pack up and move onto the next job. We get it. However, there are a few more very important tasks to complete, such as testing, safety checks, and maintaining good communication with your client.

13. Skipping testing and safety checks

Thorough safety checks after an installation are one of the most important steps of the entire process. Failure to conduct safety tests and checks increases liability for you and the property owner and can lead to accidents or personal injury.

Cycle the door several times after installation. Examine its performance closely from the interior and exterior. Be sure to test all safety features, including sensors, emergency releases, or automatic reversal mechanisms according to the manufacturer’s guidelines.

14. Leaving clients unprepared

Now that you’ve done your testing and safety checks, there’s one last important item: you must provide clear instructions to the building’s owner/manager for safe door operation and maintenance practices. Failing to do so makes it harder to troubleshoot future issues and increases the risks of improper door operation and premature component or system failure.

Take time to demonstrate all operational and safety features to the owner/operator in person. Train them in routine maintenance procedures, such as cleaning and lubrication. Provide instructions, maintenance guides, and warranty information for the door, operator, and other major components, such as safety features. Encourage them to register the door with the manufacturer for warranty purposes.

Some final thoughts

While many installers generally find overhead doors easy to source and install, remember that details matter. Paying close attention to them will help ensure that the doors you install will provide years of security, convenience, and reliable service.

Philip Paranicas, with the help of the team at Alpine Overhead Doors, wrote this article. Since 1972, Alpine has been manufacturing rolling overhead door systems, including service and insulated doors, fire- and storm-rated, and storefront doors, shutters, grilles, and high-performance coiling doors.