FEMA-Tite™ - P-361 Rated Rolling Tornado / Hurricane Door

Product Features

- Designed, tested and certified as ICC 500-2020/FEMA P-361-2021 rated doors

- Resists flying debris caused by extreme winds

- R-value of 9.00/U-factor of .111

- Certified from (3ft-6in w x 4ft h) up to (20ft w x 20ft h)

- This Smart Security System will close multiple doors upon alarm

Alpine’s FEMA-TITE™ rolling door is ideal for safe rooms, storm shelters for schools, office buildings, emergency call centers, police stations, post offices or anywhere that may be subject to hurricanes or tornados.

Functional Benefits

- Alpine’s Insulated Metal Backed model FEMA-TITE™ metal on metal insulated slat has polystyrene insulation at a min 15/16” thick with an option for CFC-Free Foamed-in-Place Polyurethane and helps reduce air infiltration.

- A minimum gauge combination of 16ga front slat and 16ga back slat has been missile tested to ensure safety against flying debris.

- Doors are designed to withstand a wind speed of 250mph for tornadoes and 200mph for hurricanes

- “Fail Safe” electric operator which will close the door upon alarm at a rate of 9” per second on average

- All operating systems can be adapted to specific conditions such as; inclement weather, corrosive atmospheres, etc.

- Air infiltration – manufactured to meet 2015. IECC®, ASHRAE®90.1 and California’s Title 24, tested independently to meet 0.3 CFM/FT

- Weather seals consist of a neoprene hood baffle, vinyl guide weather stripping and vinyl astragal on the bottom bar, with an option for 1½” perimeter brush seals

- Not to be mounted to CMU block, filled or hollow.

Certifications

FEMA-TITE™ rolling storm shutters are certified by PRI to ICC 500-2020/FEMA P-361-2021 as follows:

- Design Pressure = 254psf / Test Pressure = 305psf

- Missile Impact = 13ft / 15lb 2×4 @ 100MPH

- Maximum Tested Size = 20ft Width x 20ft Height

- Minimum Tested Size = 3ft-6in Width x 4ft Height

- Click here to download the certification (PDF)

The Alpine Advantage and Benefit

- Our available “Fail safe” operators can be used in combination with wind sensors and tied directly to security or alarm systems.

- Alpine Insulated Metal Backed (IMB) Doors are designed for easy operation and are trouble free with minimal maintenance required.

- After 42 years in this family business, Alpine doors have been proven reliable for use on thousands of installations in Commercial and Business locations. Alpine’s quality and workmanship is well known throughout the door industry. Our hands-on approach to every job ensures customer satisfaction.

- With a “Made-to-Order” manufacturing process. Alpine builds your product to the exact size, specifications and requirements.

- All of our products are constructed to have a rigid and compact design which provides for a more structural grade product while reducing overhead space and obstruction.

- Alpine builds trust by providing our products with a two-year warranty on material and workmanship. As we also offer an optional five-year prorated warranty.

- We are an ISO 9001:2015 registered firm which ensures that our products are built with strict quality control you can count on.

Installation

- Rolling doors as manufactured by Alpine Overhead Doors, Inc. provide years of trouble-free operation. Not to be mounted on CMU block, filled or hollow.

- Opening preparation, miscellaneous or structural metal work, access doors, finish or field painting, field electrical wiring, wire, conduit, fuses and disconnect switches are in the Scope of Work of other divisions or trades.

Curtain

Constructed of Interlocking, roll-formed 3” galvanized or stainless steel dual walled flat slats, 1” thick, Structural Quality Grade D, as per ASTM-A653/A653-M with Polystyrene or CFC-Free Foamed-in-Place Polyurethane insulation providing an R-value of 9.00 (U-Factor of 0.111) that provides protection against air infiltration and life-threatening weather conditions.

Front/Back Gauge Combinations: Galvanized Steel: 16/16 or Stainless Steel.

OPTION: Vision Lights Available.

Galvanized Endlocks/Windlocks

Ductile Cast iron, hot-dipped galvanized wind locks are riveted to the ends of each slat with 1/4” rivets. Furnish windlocks on every slat based on FEMA 361/ICC500 wind load requirements.

Bottom Bar

Two roll-formed galvanized steel or stainless-steel angles which are designed to reinforce the bottom of the curtain. Equipped with rubber astragal or a sensing edge which extends into the guides. Galvanized steel as per ASTM-A653/A653-M.

OPTION: Structural Steel angles with exclusive Exo-Shield™ powder coating, or Stainless Steel to match curtain.

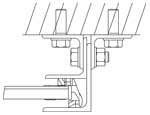

Guides

Alpine’s TD Guide mounting system is designed using dual structural steel wall angles mounted to steel or poured concrete with guides sandwiched between them providing the strength needed to meet the FEMA 361 wind load requirements of 240psf.

The dual mounting angles provided for each jamb shall be continuous and fastened to the structure using minimum 1/2 fasteners or welds at 18” O.C. Not to be mounted to CMU block, filled or hollow.

Spring Counterbalance

To be housed in a steel pipe with a diameter and wall thickness to restrict maximum deflection to 0.03” per foot of door width. Springs are of the helical torsion type which are designed to include an overload factor of 25% for optimum ease of operation. The springs are grease packed and mounted on a cold rolled steel inner shaft. Spring tension is adjustable from the outside of the end bracket plate.

Sealed ball bearings prevent wear on the pipe shaft.

Life Cycles: 20,000 Standard; High life cycles available upon request. The springs are computer designed to effectively counterbalance the door for high numbers of life cycles of operation.

Stop Lock Bearing

Stop Lock Bearing which prevents the door from free falling in the event of a drive operation failure.

Brackets

Carbon Steel plate not less than 1/4” thick with ball bearings at rotating support points on both brackets. When bolted to the wall, the mounting angle that supports the barrel/pipe assembly and forms an end enclosure.

OPTION: Hot Dipped Galvanized or Stainless Steel.

Hood

Made from 22 Gauge galvanized steel and formed to fit the contour of the end brackets and is combined with a lintel brush seal to resist air infiltration.

Style Options: Hexagon, Square or Round.

Finish Options: Galvanized with exclusive Exo-Shield™ powder coat or Stainless Steel.

Optional galvanized back fascia available for use when the area behind the hood is exposed the optional feature is especially applicable with pre-engineered buildings. Available with Exo-Shield™ powder coat to match the curtain or hood.

Finishes

Slats are prepared with a minimum galvanizing of G-60. The hoods are galvanized and other exposed ferrous surfaces are either prime painted or Exo-Shield™ powder coated. 188 Powder Coat colors to choose from with the option for custom colors and environmental requirements. Please See Alpine’s Color Selection Page: (www.alpinedoors.com/colors_standard.htm)

LOCKING

Option 1*: Pad-lockable slide locks for latching and locking the door on the coil side of the bottom bar.

Option 2*: Keyed Cylinder Locks.

Option 3: Pad-lockable chain keeper mounted to guides for hand chain operated doors.

Option 4: Gear reduced motor acts as lock.

*Electric lock sensors required on doors with options 1 and 2.

HOT DIP GALVANIZING (OPTION*)

Option applied to the guides, brackets, wall angles and gears in addition to Standard Specifications. Applied where conditions of extreme or unusual atmospheric contamination is present. As per ASTM -A123.

Pipe-Shafts are to be Zinc Enriched Powder coated or Stainless Steel.

Alpine Motor Operators

UL Listed inline planetary gear drive “Fail Safe” operator. Operator is designed to close door upon loss of power or alarm activation.

Horsepower as recommended by manufacturer.

Available in 115/230V Single Phase or 230/460V Three phase.

Contact Alpine to learn more about this motor operator today!

To download PDF drawings for FEMA-Tite™, please select from links below.

> For CAD files, please click here

The FEMA-Tite™ IMB-V9 AutoCAD drawing and AutoCAD detail are for informational purposes. They may change at any time. They comply with 080000 and 08330 construction specifications pertaining to roll up doors. The CAD detail and CAD drawing reflect the options that are available to the architects and engineers compiling an AutoCAD drawing to present to contractors. 08000 and 08330 Construction of rolling and coiling doors is reflected in the CAD drawing and CAD detail. Counter shutters may be found on the left of this page. Roll up steel door drawing details files may be obtained at the top left of this page.

A new introduction of AutoCAD Drawing Generator is now available on Alpines public website: http://WebGen.Alpinedoors.com/. Register and generate your drawing by clicking on CAD Drawing Download.

First time Users please register and immediately generate AutoCAD DXF drawings and PDF downloads.

Note: Please Retain all drawing numbers to retrieve and modify your drawing with our Alpine Engineering Team

The roll up metal coiling doors AutoCAD detail and AutoCAD drawing will be updated regularly. Alpine’s roll up steel door and rolling metal doors are built to last.

Model FEMA-TITE™

3” Dual Walled Insulated Slats

Rolling Service Door

> Download 3 Part Specifications (PDF)

> Download 3 Part Specifications (DOC)

NOTE: For specifications, architects must choose from a variety of options. The standard choice will be shown first in plain text followed by the options shown in [brackets] (Example “Finish: Galvanized, [Powder coated] [Baked enamel]”). The specifier must make the appropriate choices and delete the others (Example: “Finish: ExoShield™ Powder coated”).

GENERAL

1.01 SUMMARY

A. This section includes: Electric operated “Auto-Close” 1.0” thick Insulated Metal Backed Rolling Door.

1. Cycle life: Design doors of standard construction for normal use of 20,000 cycles standard

2. Design doors to withstand a wind load of 250 psf (tornado)(300psf test at 1.2 times the design pressure

3.Design doors to withstand a wind load of 200 psf (hurricane)(300psf test at 1.5 times the design pressure

B. Related Sections: Related to this section, but not limited to, the following (based on Master Format 2004):

1. Section 01660 – Product Storage and Handling Requirements.

2. Section 04220 – Concrete Unit Masonry.

3. Section 05120 – Structural Steel

4. Section 05500 – Metal Fabrications.

5. Section 06100 – Rough Carpentry.

6. Section 08310 – Access Doors and Panels.

7. Section 08710 – Door Hardware.

8. Section 09290 – Gypsum Board.

9. Section 09900 – Paints and Coatings.

10. Section 26000 – Electrical.

1.02 REFERENCES

A. ASTM A 653/A 653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process

B. ASTM A 36 – Standard Specification for Carbon Structural Steel, Hot Rolled Steel

C. ASTM A 123 – Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

D. ASTM A 312 – Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

E. ASTM A 240 – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

F. ASTM A 276 – Standard Specification for Stainless Steel Bars and Shapes

G. ASTM B 209 – Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

H. ASTM B 221 – Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

I. ASTM D 4549 – Standard Specification for Polystyrene and Rubber-Modified Polystyrene Molding and Extruding Materials (PS)

1.03 SUBMITTALS

A. Submit under provisions of Section 01300.

B. Product Data: Provide manufacturer’s standard details and catalog data. Provide installation instructions.

C. Shop Drawings: Furnish shop drawings for architect’s approval. Include elevation, sections, and details indicating dimensions, materials, finishes, conditions for anchorage and support of each door.

D. Submit manufacturer’s recommended operation, troubleshooting, and maintenance instructions

E. Product certificate of compliance with ICC 500-2020 ICC/NSSA Standard for the Design and Construction of Storm Shelters

F. Product certificate of compliance with FEMA 361 Safe Rooms for Tornados and Hurricanes

G. Product certificate of compliance to sustain 300 psf wind pressure in accordance with ASTM E330

H. Product certificate of compliance in accordance with the requirements of ASTM E1886 Large Missile Impact for FEMA 361 assemblies.

1.04 QUALITY ASSURANCE

A. Manufacturer: Rolling doors shall be manufactured by a firm with a minimum of five years experience in manufacturing fire and smoke control doors of the type specified.

B. ISO 9001:2015 Qualified

C. Single-Source Responsibility: Manufacturer shall provide doors, tracks, motors, and accessories for each type of door. Secondary components shall come from a source acceptable to the manufacturer of the primary components.

1.05 DELIVERY, STORAGE, AND HANDLING

A. Deliver materials in original packaging supplied by manufacturer with intact labels. Store materials away from harmful environmental conditions and construction.

1.06 WARRANTY

A. Door Warranty: Provide a one year written warranty from the date of substantial completion against deficiencies due to defects in materials or workmanship. Installer agrees to repair or replace any defects in materials or workmanship.

B. Project Warranty: Refer to Conditions of the Contract for project warranty provisions.

PART 2 – PRODUCTS

2.01 MANUFACTURER

A. Manufacturer: Alpine Overhead Doors, Inc.; 8 Hulse Road Suite 1S, East Setauket, NY 11733. Telephone 800-257-4634 or 631-473-9300. Fax 631-642-0800.

B. Model: FEMA IMB V9® Insulated Rolling Service Door

Substitutions: No substitutions permitted

2.02 MATERIALS

A. Curtain:

1. Slats: Constructed of 1.0” thick interlocking, roll-formed Insulated Metal Backed (IMB) V9 slats. (Slat construction allows for dual coiling flexibility)

a) Slat/Back Cover Material:

i) Galvanized steel, Structural Quality Grade D, as per ASTM A 653/ A 653 M

Finish (Can be different for exterior/interior): Galvanized [ExoShield™ Powder coating] [Baked enamel] (Minimum coating conforming with Coating Designation G-01 is required)

– OR –

ii) ASTM 240 Stainless steel 300 series Finish (Can be different for slat and back cover): [Mill finish #2B] [#4 satin finish]

b) Insulation: Polystyrene [foamed-in-place Polyurethane]

i) Insulation Thickness: 15/16”

ii) R-Value: 1.0” inch thick slats with an R-Value: 9.00 (U-factor of 0.111) calculated using the ASHRAE Handbook of Fundamentals. and an STC rating of 26, for insulation and noise control.

c) Gauge: (Per manufacturer’s standard)

i) Front/Back slat: Galvanized Steel: 16/16

ii) Front/Back slat: Stainless Steel 16/16.

2. Wind Locks: Continuous – Required

a) Ductile cast iron, hot-dip galvanized wind locks riveted (solid rivets, minimum 3/16” thick) to each end of every slat to prevent lateral movement and to limit slat deflection and bending stress.

3. Bottom Bar:

a) Two structural formed galvanized steel [stainless steel] angles which extend into guides, designed to reinforce curtain bottom. (Size dependent on dimensions per manufacturer’s standard)

i) Galvanized Steel as per ASTM A 653/ A 653 M

Finish: Gray baked enamel [Galvanized] [ExoShield™ Powder Coated]

– OR –

ii) ASTM 240 Stainless Steel 300 Series

Finish: [Mill finish #2B] [#4 satin finish]

[Vision Lite panels]: Provide 6” by 1 ¼” oval acrylic panes set into curtain. (Choose number and placement)

B. Guides:

1. Guides shall be designed using structural angles with removable bellmouth curtain stops to allow for curtain maintenance without removal of guides. Bellmouth stops shall be flush with guide groove. Guides shall be fastened with minimum 3/8” bolts at minimum 18” o.c. Wall mounting angles shall be fastened to the wall at 18” o.c. whether welded to steel or anchored to poured concrete.

a) Material:

i) ASTM A 36 Carbon Structural Steel

Finish: Gray ExoShield™ powder coated [ASTM A 123 Galvanized]

– OR –

ii) ASTM 276 Stainless Steel 300 Series

Finish: Mill finish #2B

C. Door Support Brackets and Mounting Plates:

1. Steel plate not less than 1/4” thick. Provide ball bearings at rotating support points. Bolt plates to wall mounting angles with minimum 1/2″ fasteners. Plate supports counterbalance assembly and forms end enclosures.

a) Material:

i) ASTM A 36 Carbon Steel:

Finish: Gray ExoShield™ Powder coated [ASTM A 123 Galvanized]

– OR –

ii) ASTM 240 Stainless Steel 300 Series

Finish: [Mill Finish #2B]

b) [Stop Lock bearing]: To prevent door from free falling in the event drive operation fails.

D. Counterbalance Assembly: TorsionCounterbalance assembly: Steel pipe barrel of a size capable of carrying a curtain load with a maximum deflection of 0.03” per foot of door width. Heat-treated helical torsion springs encased in a steel pipe and designed to include an overload factor of 25% to ensure minimum effort to operate. Sealed and prelubricated high speed ball bearing at rotating support points. Torsion spring charge wheel for applying spring torque and for future adjustments.

a) Material:

i) ASTM A 36 Carbon Structural Steel

Finish: Clear coat of rust inhibitor [Zinc Enriched Powder coated]

– OR –

ii) A 312 Stainless Steel 300 Series

Finish: Mill finish

b) Life Cycle: Springs designed to satisfy 20,000 cycles. (Cycle defined as one time opening and closing of door)

E. Hood:

1. 22 gauge galvanized steel formed to fit the contour of the end brackets with reinforced top and bottom edges. Provide support bracing for doors wider than 20 feet at every 10 feet to prevent excessive sag. Fastened to end brackets.

2. Shape: Hexagon [square] [round]

3. Material:

a) Galvanized Steel as per ASTM A 653/ A 653 M

Finish: [Baked enamel paint] [ExoShield™ Powder coated]

– OR –

b) ASTM 240 Stainless Steel 300 Series:

Finish: [Mill finish #2B] [#4 satin finish]

4. [Fascia]: Galvanized [Stainless Steel] provided where areas behind door hood are open. Materials and finish same as hood.

F. Locking:

1. Slide locks: Provide padlockable slide locks for latching and locking door on coil side bottom bar at each jamb extending into slots in guides. [Cylinder Locks] (Electric Interlocks recommended with motorized doors only)

2. Manual chain hoist: Provide padlockable chain keeper on guide.

G. Weatherstripping:

1. Bottom Bar: Vinyl astragal.

2. Guides: Snap-on vinyl.

3. Hood: Neoprene baffle.

4. [Lintel baffle]

2.03 OPERATION:

A. Opening/Closing:

Motor Operators:

a) Model Redi-Reset™ inline gear drive motor operator, UL Listed, 3/4 HP minimum, TENV motor, auxiliary chain hoist, internal speed governor, solenoid actuated brake, adjustable limit switches, delay on reverse*, non-resettable cycle counter, adjustable reclose timer*, 3-button open-close-stop wall mount control station, NEMA 1 enclosures. Motor operator shall be mounted horizontally in front of coil and shall not require additional clearance above the top of the coil. Operator shall automatically close the door in an emergency with “Fail-Safe” function. After power is restored, and alarm is cleared, motor operator shall be ready to operate normally.

2. [Sensing Edges] (For double angle bottom bar): For motorized doors, sensing edges allow door to go up in case of obstruction. [Pneumatic Edge] [Electric Edge] [Wireless Edge].

a) Colors: Gray [Yellow] [Black] [White] [Yellow with black stripes]

2.04 Mounting:

1. Interior face mounted on prepared opening.

2. Interior mounted between jambs and under lintel in a prepared opening.

3. Exterior face mounted on prepared opening.

PART 3 – EXECUTION

3.01 EXAMINATION

A. Verify that dimensions are correct and project conditions are in accordance with manufacturer’s installation instructions; do not proceed with installation until unacceptable conditions have been corrected.

3.02 INSTALLATION

A. Install units in accordance with manufacturer’s instructions.

B. Ensure that units are installed plumb and true, free of warp or twist, and within tolerances specified by the manufacturer for smooth operation.

3.03 FIELD TESTING

A. Test doors for regular operation.

3.04 DEMONSTRATION

A. Instruct the Owner’s personnel in correct operation and maintenance of units.

3.05 ADJUST AND CLEAN

A. Clean units in accordance with manufacturer’s instructions.

B. Restore slight blemishes in finishes in accordance with manufacturer’s instructions to match original finish. Remove and provide new units where repairs are not acceptable to the Architect.

Alpine has designed and built this ultimate performance FEMA-compliant rolling storm shutter that provides stronger protection against extreme weather conditions with high winds that may cause flying debris. In the event of an emergency these doors can act as a protection against the aforementioned winds as well as unwanted intrusions. To help businesses cut down on energy costs, the model FEMA-Tite insulated door is designed specifically to provide energy efficiency, utilizing a heat resistant polystyrene insulation or CFC-Free Foamed-in-Place Polyurethane with a low thermal transmittance factor.

> Click here to see our full line of hurricane rated rolling storm doors.

The metal on metal insulated slat of this rolling overhead door has polystyrene insulation, or CFC-Free Foamed-in-Place Polyurethane that is a minimum of 15/16″ thick. Slats are available in the following gauge combination 16 Front/16 Back with a thermal break on each slat.

FEMA-TITE™ Slat Profile